The Role of Xanthan Gum in Cosmetics Manufacturingc

In the world of cosmetic manufacturing, one of the key challenges is to find raw materials that offer versatility, stability, and excellent performance across a variety of formulations. Xanthan Gum has emerged as a top choice for manufacturers, offering outstanding benefits for the creation of Non-Ionic Emulsifiers. This natural polysaccharide not only enhances texture and viscosity but also plays a critical role in stabilizing emulsions and improving the overall quality of cosmetic products.

Whether you’re creating lotions, creams, shampoos, or personal care products, E415 can serve as an essential component in your formulations. Its ability to create stable emulsions, enhance the sensory experience, and offer long-lasting product stability makes it a must-have for cosmetics manufacturers. In this comprehensive guide, we’ll dive deeper into why E415 is the perfect raw material for cosmetic formulators, particularly in the context of Non-Ionic Emulsifiers.

What is Xanthan Gum?

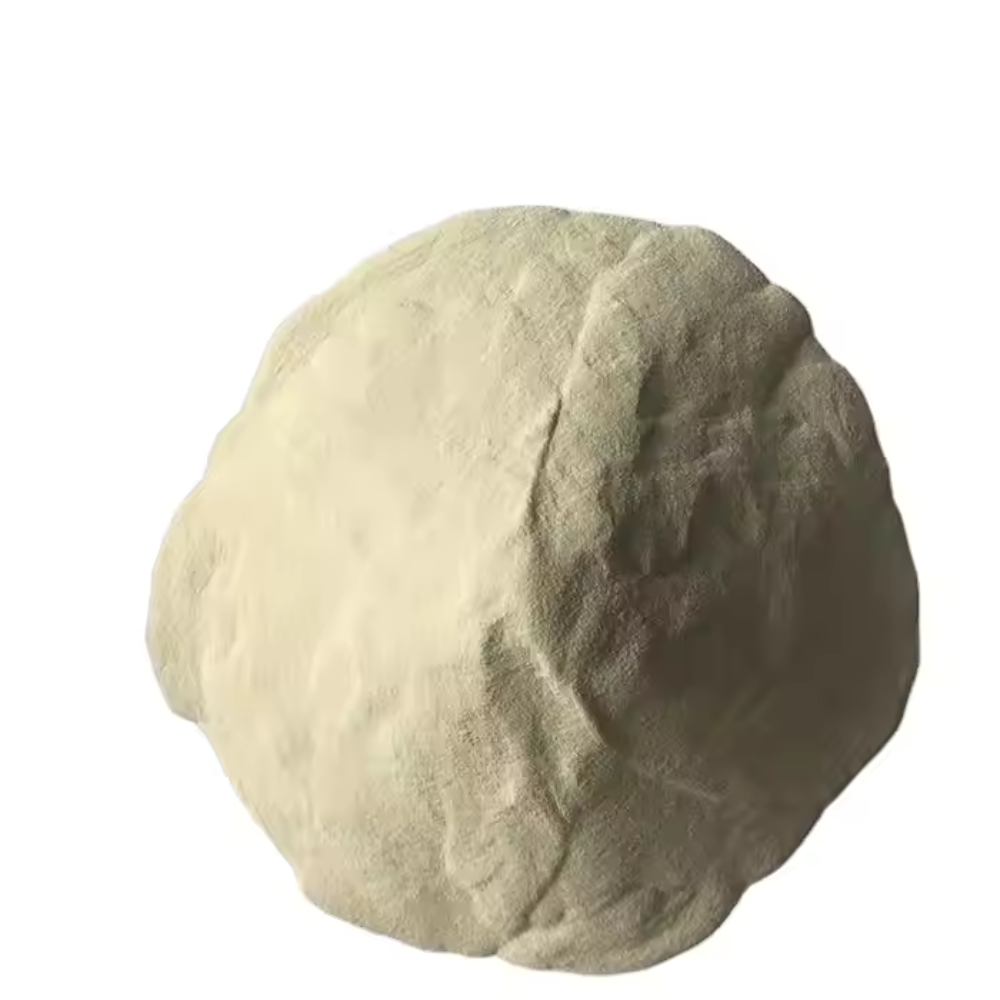

Xanthan Gum is a natural, water-soluble polysaccharide produced by the bacterial fermentation of sugars, typically derived from corn, wheat, or soy. The process involves the bacterium Xanthomonas campestris, which produces a gel-like substance that is then dried and ground into a fine powder. Xanthan Gum is used extensively in industries such as food production, pharmaceuticals, and cosmetics because of its outstanding ability to increase viscosity and stabilize emulsions.

In cosmetics, E415 functions as a stabilizer, thickener, and emulsifier. It helps combine oil and water-based ingredients that would otherwise separate, providing a smooth, consistent texture. E415 is most commonly used in the production of Non-Ionic Emulsifiers, where it plays a pivotal role in ensuring the formulation remains homogenous over time.

For more information on the versatility of E415, you can refer to the article published by the US National Library of Medicine on its uses in the cosmetics and pharmaceutical industries.

Benefits of Xanthan Gum for Non-Ionic Emulsifiers in Cosmetics Manufacturing

1. Stabilizing Emulsions

The ability to stabilize emulsions is one of the most important functions of E415 in cosmetic formulations. Non-Ionic Emulsifiers rely on ingredients that can effectively combine water and oil into a single, uniform product. E415 stabilizes these emulsions, preventing the ingredients from separating over time. This ensures that your cosmetic products maintain their quality and consistency throughout their shelf life.

The role of emulsifiers in cosmetic formulations is further discussed by Cosmetic Chemists, emphasizing the importance of proper emulsification for creating stable and high-performance cosmetic products.

2. Improved Viscosity Control

For cosmetic manufacturers, controlling viscosity is essential to achieving the desired product texture. Whether formulating a rich, creamy lotion or a lightweight serum, Xanthan Gum allows for precise viscosity control. Its ability to thicken products without creating a greasy or heavy feel is one of the reasons it is favored for Non-Ionic Emulsifiers.

With its remarkable thickening ability, Xanthan Gum helps ensure that your products have the right consistency, which is essential for the end-user experience. Whether you’re producing a gel, cream, or liquid formula, E415 can be used to fine-tune the texture and ensure it performs as expected.

3. Enhanced Stability and Shelf Life

Stability is crucial for cosmetic products, particularly in Non-Ionic Emulsifiers, where varying temperatures and storage conditions can lead to phase separation or texture degradation. E415 contributes to the long-term stability of emulsions, ensuring that your product remains homogeneous over time.

Its water-retention properties and ability to maintain consistency in extreme conditions (such as heat or freezing) help extend the shelf life of your cosmetic products. This makes Bulk Xanthan Gum an excellent investment for manufacturers who prioritize durability and performance.

4. Natural and Safe

As consumers become increasingly aware of the ingredients used in personal care products, there is growing demand for natural, non-toxic ingredients. Xanthan Gum meets these criteria, as it is derived from natural sources and is generally recognized as safe for use in cosmetics. It is also non-irritating and hypoallergenic, making it suitable for sensitive skin formulations.

Given its safety profile, Xanthan Gum has become a preferred choice for manufacturers looking to formulate clean and skin-friendly cosmetics. Learn more about the natural and safe properties of E415 on the National Institute of Health website.

5. Improved Texture and Sensory Experience

In addition to its functional properties, E415 improves the sensory experience of cosmetic products. It imparts a silky-smooth texture to formulations, which enhances their ease of application and overall feel. The pleasant texture makes it ideal for products like moisturizers, gels, and lotions, where a smooth and velvety finish is desired.

This sensory benefit is especially important for Non-Ionic Emulsifiers, where achieving the right texture is essential for customer satisfaction. Xanthan Gum ensures that the end product has the right consistency, without being too greasy or too thin.

Why Choose Xanthan Gum for Non-Ionic Emulsifiers?

1. Versatility in Multiple Formulations

E415 is compatible with a wide range of ingredients, making it a versatile addition to almost any cosmetic formulation. From Non-Ionic Emulsifiers in creams and lotions to its use in haircare products like shampoos and conditioners, E415 helps create smooth, stable emulsions that perform reliably.

Manufacturers can use E415 in various product types, including facial care, body care, and hair care. It blends well with both natural and synthetic ingredients, making it a staple for product developers seeking flexibility and performance.

2. Cost-Effective and Accessible

One of the primary concerns for cosmetic manufacturers is managing costs while maintaining high product quality. Wholesale E415 offers a cost-effective solution without compromising on performance. By purchasing in bulk, manufacturers can reduce costs while ensuring a steady supply of this critical ingredient.

Additionally, E415 is widely available, which means that manufacturers can rely on a steady, uninterrupted supply chain. This is essential for businesses that require regular deliveries of raw materials to maintain production schedules.

3. Reliable Supply and Consistent Quality

When sourcing raw materials, consistency is key. E415 offers reliable quality with each batch, ensuring that formulations remain consistent from one production cycle to the next. As a Xanthan Gum Supplier, we guarantee that every batch of Bulk E415 meets strict quality standards, ensuring that your products perform at their best.

Our partnership with global suppliers ensures that your supply of E415 is always on time and of the highest quality. For more information about quality standards in the cosmetics industry, check out this article on Cosmetic Product Standards.

Complementary Products: Enhance Your Formulation with These Related Xanthan Gums

While Xanthan Gum is highly effective on its own, it can be combined with other ingredients to enhance its performance in certain formulations:

- Guar Gum: A natural polymer similar to E415, Guar Gum can be used in combination with E415 to increase the thickness of emulsions. It also offers additional film-forming properties that can improve product texture.

- Hydroxyethylcellulose: This cellulose derivative is another great emulsifying agent that can be used alongside E415 to boost the viscosity and stability of products. It is particularly useful in transparent gels and other clear formulations.

- Carbomer: Often used in gel-based formulations, Carbomer can be paired with E415 to further enhance viscosity and improve product flow. It is ideal for creating non-oily, clear gels.

These ingredients can complement E415 and offer additional functional properties depending on the type of product being developed.

Conclusion: Why Bulk Xanthan Gum is Essential for Your Cosmetics Business

Choosing the right raw materials is vital to creating high-quality, stable, and marketable cosmetic products. With its superior ability to stabilize emulsions, control viscosity, and improve product texture, E415 is an indispensable ingredient for Non-Ionic Emulsifiers in cosmetics manufacturing.

By purchasing Bulk Xanthan Gum, you can ensure your production process runs smoothly, your formulations perform reliably, and your products meet consumer expectations. With its competitive pricing, natural sourcing, and consistent quality, E415 is the ideal raw material for manufacturers looking to enhance their cosmetic formulations.

Reviews

There are no reviews yet.