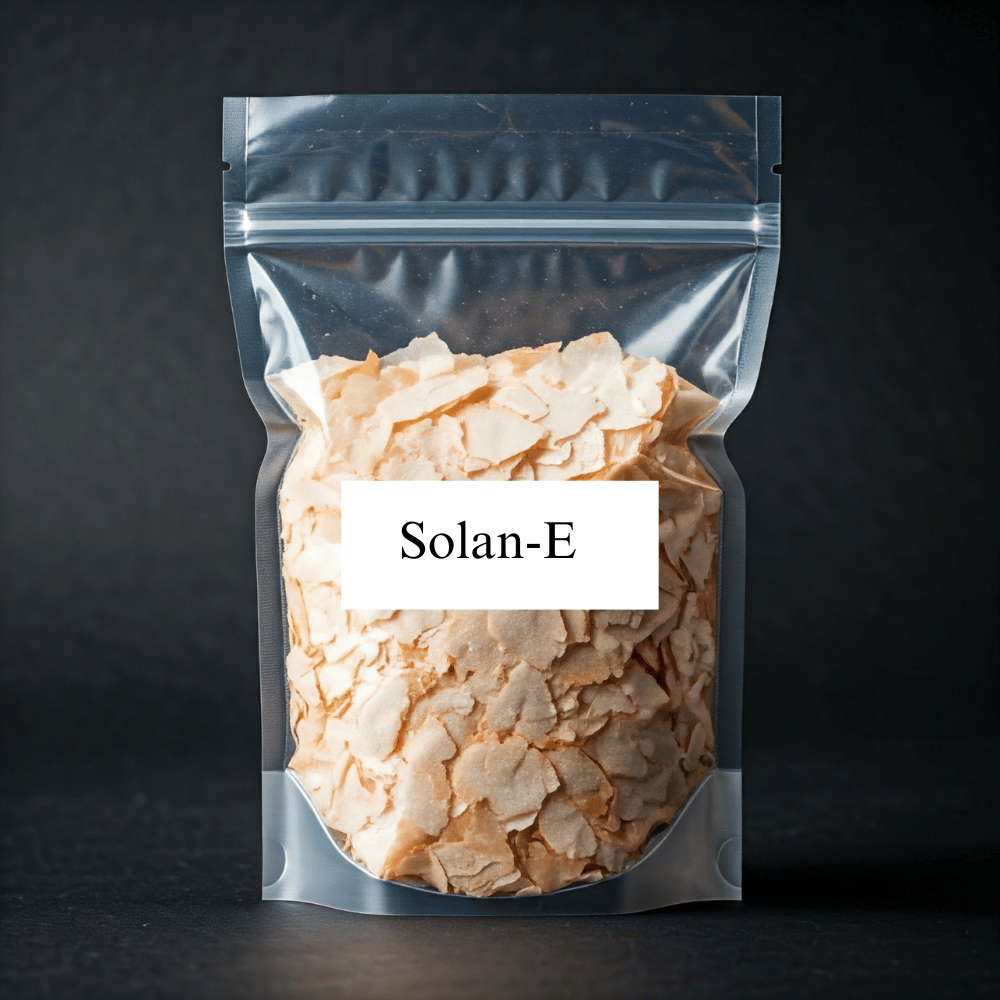

Sodium Hydroxide Caustic Soda for Soap Base Manufacturing: A Vital Raw Material for Cosmetics

Sodium Hydroxide, commonly known as caustic soda, is a highly versatile and essential raw material in the cosmetics manufacturing industry, particularly for soap base production. As a key ingredient, its powerful properties make it indispensable in the formulation of soaps, ensuring that manufacturers deliver high-quality, effective products. For soap base manufacturers seeking consistency, efficiency, and performance in their formulations, Bulk NaOH is the perfect solution.

Why Sodium Hydroxide Caustic Soda Is Essential for Soap Base Manufacturing

Sodium hydroxide caustic soda is used in various applications within cosmetics, but its primary use is in saponification—the chemical process that produces soap. When mixed with oils and fats, caustic soda breaks them down, creating soap and glycerin. For soap base manufacturers, this process is crucial because it ensures the creation of a firm, clean product that retains its integrity during production and usage.

For further reading on the chemistry of saponification and its role in soap-making, visit Wikipedia’s article on Saponification.

Key Benefits of Using Sodium Hydroxide Caustic Soda in Soap Bases

- Effective Saponification Process: NaOH is the driving force behind the saponification reaction, which turns oils into soap. This critical function ensures that manufacturers can create consistent and high-quality soap bases that meet industry standards.

- Improved Soap Texture: The caustic soda creates a solid and consistent texture in soap bases. This helps manufacturers deliver soap products that have the right consistency, making them easier to mold, cut, and shape during production.

- Cleansing Properties: The chemical also enhances the soap’s ability to cleanse, giving soap bases a higher effectiveness at removing impurities, oils, and dirt. This makes it a key ingredient for manufacturers looking to create products that are both gentle and effective on the skin.

- Customization for Different Formulations: NaOH allows soap base manufacturers to customize the soap’s hardness, lather, and overall performance. It gives the flexibility to create premium soap formulations for various cosmetic and skincare products.

- Cost-Effective Manufacturing: Buying Bulk NaOH from reliable wholesalers at wholesale prices ensures that manufacturers can keep production costs low without compromising on quality. The high demand for sodium hydroxide makes it readily available in the market, further ensuring uninterrupted production cycles.

How Sodium Hydroxide Caustic Soda Is Used in Soap Base Manufacturing

The process of soap base creation is straightforward but requires careful handling of NaOH. Here’s how manufacturers incorporate this chemical into their formulations:

- Mixing with Oils: Sodium hydroxide is combined with oils such as coconut oil, palm oil, or vegetable oil to begin the saponification process. The result is a mixture that, over time, forms into soap base.

- Reaction and Formation: The sodium hydroxide acts as a catalyst in this chemical reaction, breaking down the oils and converting them into soap. The higher the purity of the sodium hydroxide, the better the final soap base will be.

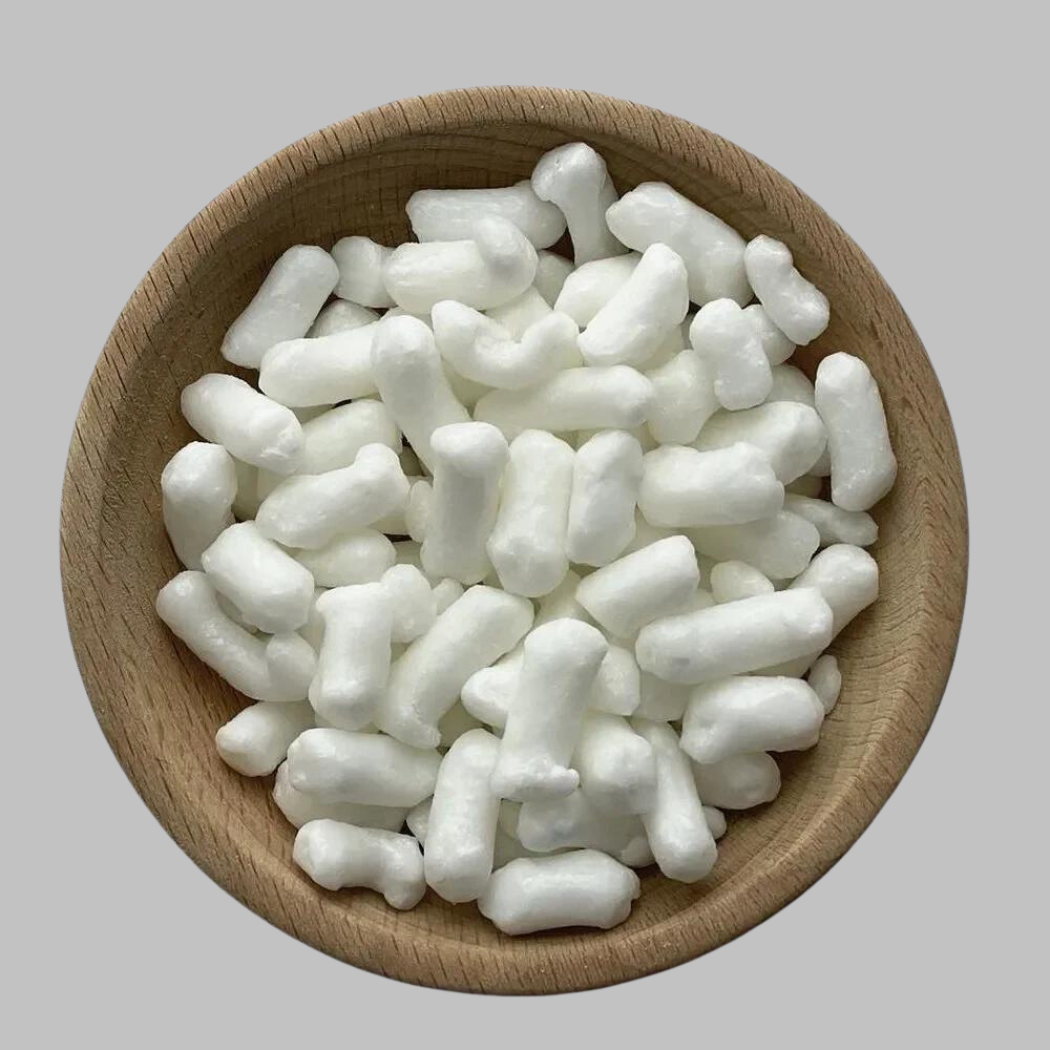

- Cooling and Molding: Once the saponification process is complete, the soap mixture is allowed to cool and solidify, taking on a firm texture ideal for molding into bars or blocks. Manufacturers can control the shape and size of the soap base according to their specifications.

- Additional Customization: After the soap base is formed, further ingredients such as fragrance oils, colorants, or exfoliating agents can be added to enhance the product’s aesthetic and functional properties.

For a deeper understanding of the soap-making process, check out The Soap Making Resource.

Why Choose Us as Your (NaOH) Supplier?

As a leading Wholesale sodiuam hydroxide Supplier and Distributor in Pakistan, we understand the unique needs of soap base manufacturers. We offer bulk quantities of premium-grade NaOH, sourced from reliable producers. Our product is designed to meet the high standards of cosmetic manufacturers who require consistency, purity, and quality in their raw materials.

Here’s why manufacturers trust us for their sodium hydroxide needs:

- High Purity: Our Sodium Hydroxide Caustic Soda has a high purity level, ensuring that the saponification process is smooth, effective, and reliable, leading to superior soap bases.

- Competitive Pricing: We offer some of the best prices in Pakistan for bulk sodiuam hydroxide, ensuring that you can manage production costs without compromising on quality.

- Timely Delivery: We prioritize timely delivery to ensure that your manufacturing schedules are not disrupted. Our bulk sodiuam hydroxide is always available when you need it.

- Trusted Supplier: With years of experience, we have built a reputation as a trusted distributor and supplier of sodiuam hydroxide. Our customer support team is always ready to assist with any questions or concerns you may have.

Complementary Products for Soap Base Manufacturing

When it comes to formulating high-quality soap bases, there are several other ingredients that work well with NaOH. Consider these complementary products to enhance your formulations:

- Glycerin: A natural byproduct of the saponification process, glycerin is a humectant that draws moisture to the skin, making it an ideal ingredient in moisturizing soap bases. Learn more about glycerin at PubChem Glycerin.

- Coconut Oil: Known for its lathering properties, coconut oil works exceptionally well with sodium hydroxide in soap base formulations, giving the soap a rich lather and deep cleansing action. For more on coconut oil’s role in soap making, visit Coconut Oil in Soap Making.

- Palm Oil: Often used in combination with sodium hydroxide, palm oil contributes to the hardness of the soap base and adds skin-conditioning properties. Learn about the benefits of palm oil on The Palm Oil Facts.

These ingredients, combined with (NaOH), allow manufacturers to create a range of premium soap bases tailored to different consumer needs.

Final Thoughts on Sodium Hydroxide Caustic Soda for Soap Base Manufacturers

Sodium Hydroxide Caustic Soda is a cornerstone ingredient in soap base manufacturing. Its effectiveness in saponification, ability to customize soap formulations, and cost-effectiveness make it an essential choice for cosmetic manufacturers. By sourcing high-quality bulk sodium hydroxide caustic soda from trusted suppliers, manufacturers can ensure the production of soap bases that meet both consumer expectations and industry standards.

Whether you’re looking to improve the texture, cleansing power, or overall quality of your soap products, (NaOH)is the perfect raw material to achieve your manufacturing goals. Choose us as your trusted (NaOH) distributor in Pakistan, and let us help you create outstanding soap base formulations.

For more about industrial-grade chemicals used in cosmetics and soap making, visit PubChem’s Sodium Hydroxide page.

To place an order or learn more about our products, visit our Raw Materials Page.

Reviews

There are no reviews yet.